Researchers at Osaka Metropolitan University and Chiba University have succeeded in printing uniformly sized droplets with a diameter of approximately 100 µm using a liquid film of fluorescent ink. This ink, with a viscosity roughly 100 times that of water, was irradiated with an optical vortex, resulting in prints of exceptional positional accuracy at the micrometer scale.

Will printed photographs ever match the precision of a mirror’s reflection? Even though the answer may still be no for a while, scientists from Osaka Metropolitan University and Chiba University have made significant strides in precision printing with their innovative optical vortex laser-based technique that allows for the precise placement of minuscule droplets with micrometer-scale accuracy.

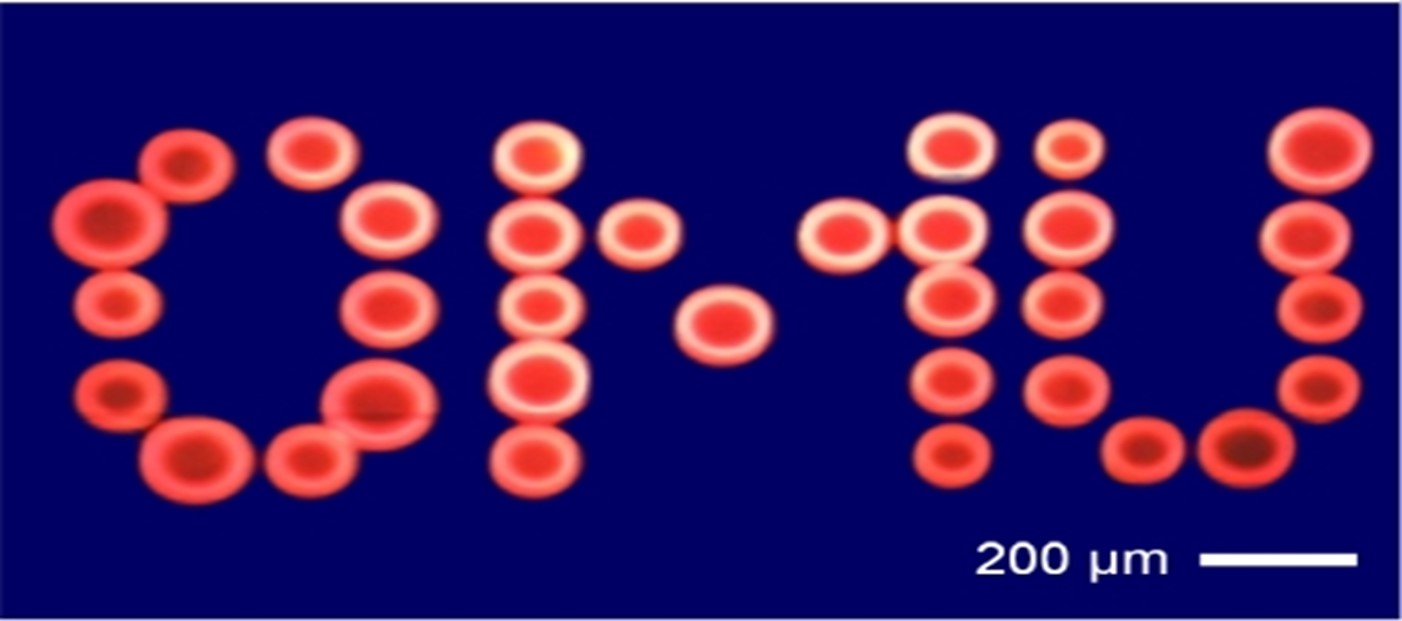

Image title: A set of 33 droplets fabricated to create “OMU” using the optical vortex laser-induced printing technique

Image caption: The novel technique precisely deposited the droplets with no satellite droplets produced

Image credit: Ken-ichi Yuyama, Osaka Metropolitan University

Usage Restrictions: News organizations may use or redistribute this image, with proper attribution, as part of the news coverage of this paper only.

Image license: Original content

Inkjet technology is a well-known printing technique that emits microdroplets from a nozzle directly onto a surface. However, when the ink droplets are viscous, with high density, the nozzle often gets clogged, a concern that has prompted the search for more advanced technologies.

A research team led by Dr. Ken-ichi Yuyama, a lecturer at the Graduate School of Science of Osaka Metropolitan University, has succeeded in printing uniformly sized droplets, with a diameter of approximately 100 µm, using a liquid film of fluorescent ink—which is approximately 100 times more viscous than water. This was achieved by irradiating the film with an optical vortex, resulting in prints of exceptional positional accuracy at the micrometer scale.

“Using a special laser beam known as an optical vortex, we have achieved stable printing of high-viscosity liquids,” explained Dr. Yuyama. “This printing technique allows for the fabrication of microdroplet laser arrays and the micropatterning of conductive nanoinks, as well as bioinks for cell scaffolds, leading to the establishment of next-generation printed photonic or electronic devices.”

The research results were published in ACS Photonics.

Funding

The authors acknowledge support in the form of KAKENHI grants-in-aid (nos. JP22H05131, JP18H03884, JP20K05242, JP22H05131, JP22H05138, JP22K18981, JP23H00270, and JP23H04600) from the Japan Society for the Promotion of Science (JSPS) and from the Core Research for Evolutional Science and Technology program (no. JPMJCR1903) of the Japan Science and Technology Agency (JST).

Conflict of interest

The authors declare no competing financial interest.

Reference:

Title of original paper: Fabrication of an array of hemispherical micro-lasers using optical vortex laser-induced forward transfer

Authors: Ken-ichi Yuyama, Haruki Kawaguchi, Rong Wei, and Takashige Omatsu

Affiliations: Graduate School of Engineering, Chiba University

Journal: ACS Photonics

DOI: 10.1021/acsphotonics.3c01005

Contact:

Ken-ichi Yuyama

Graduate School of Science, Osaka Metropolitan University

E-mail: k-yuyama[at]omu.ac.jp

Takashige Omatsu

Graduate School of Engineering, Chiba University

Email: omatsu@faculty.chiba-u.jp

Public Relations Office, Chiba University

Address: 1-33 Yayoi, Inage, Chiba 263-8522 JAPAN

Email: koho-press@chiba-u.jp

Tel: +81-43-290-2018